Rural accessibility is essential for the social and economic development of remote regions around the world. Issues with providing accessibility in Low Income Countries is exacerbated in Nepal, where the mountainous terrain and 6,000 rivers (Dhungel, 2009) make road building very challenging. In addition to this, the 7.8 magnitude earthquake in 2015 damaged many bridges (Figure 1), although very few collapsed completely (Quancai et al, 2017).

The Local Roads Network (LRN) in Nepal stands at 50,943 km, of which only 16,177 km is functional (Pande, 2014) and only about 9,000 km is in an all-season condition due to lack of maintenance and inadequate river crossings. It is maintained by the Department of Local Infrastructure (DoLI). Bridges are a key factor in developing an all-season road network. In Nepal approximately 40 bridges are under construction on the LRN (DoLI, 2019), but it was estimated in 2012 that a further 3,500 are required to make the LRN motorable and accessible throughout the year (Pande, 2014).

Presently most bridges on the LRN are constructed of reinforced concrete, cast-in-situ. The quality of construction is highly dependent on the availability of suitable sand and aggregate in the vicinity of the bridge site. Transportation time for reinforcement and cement and the capacity of the available contractors also determine the speed and quality at which bridges can be constructed (IPTM Nepal, 2015). This has been a long-term cause of concern for the Nepal government.

To address this huge demand for bridges in remote locations, different technologies and approaches need to be explored. This motivated UKaid to fund a project under the Research for Community Access Partnership (ReCAP) in 2016. Following a project workshop with key stakeholders in Nepal in January 2017 it was agreed that a modular bridge system would be appropriate, if the module size and weight could be limited to facilitate transportation to remote locations. A maximum module weight of 3 tonnes was agreed, with the length determined accordingly given the standard cross section and design of the module. Such technology is available in more developed countries but would need to be adapted for use in Nepal, and importantly would need to be designed to resist earthquake damage.

Implementation

Concrete was the preferred core material for modular bridges as cement is produced locally and therefore does not need to be imported, making the technology sustainable and cost effective. Modular construction would enable the production of units to high quality in a controlled environment. The process could also continue year-round and would not be susceptible to the annual monsoon rains, which disrupt bridge construction for several months of the year.

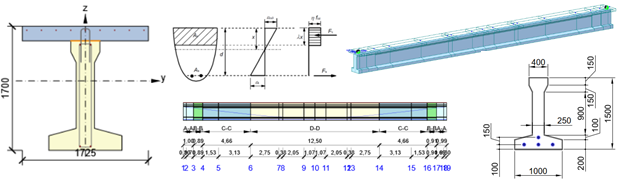

Best practice was reviewed from around the world, particularly from Thailand, Malaysia and Europe, and an appropriate design principle was agreed. A design for single span, modular bridges between 20 m and 40 m span was produced (Figure 2). The Bridge Unit of DoLI is supported by a Swiss funded technical support unit, so the design was produced by local engineers with the support of a TRL Bridge Expert.

Execution

The Nepal government let a contract to construct two trial bridges, using the new designs. One is complete in the flat Terai area of Nepal, and another is almost complete in a remote hilly area in the west. The Bridge Expert made regular visits to oversee the formwork production, fabrication of modules and assembly/prestressing on site; advising the contractor and local engineers at all stages. The contractor was also advised on safety procedures at site, and all staff were provided with appropriate personal protective equipment.

Some of the processes were already familiar, but there were new ones that the local engineers and contractors had to learn. For example the formwork had to be very accurate, so it was fabricated in steel, rather than the traditional wooden formwork. Also the Freyssinet system of cable pre-stressing was used, which involved tensioning the cable from both ends simultaneously. This required close supervision and advice from the TRL Bridge Expert.

Evaluation

The key benefits of this innovative technology are the potential to construct many more bridges more quickly, accelerating the progress of accessibility into the most rural and remote areas of Nepal. These structures will also be constructed to a higher standard than before, and are less dependent on the weather. The ultimate outcome will be better and more reliable access to thousands of communities throughout Nepal, enabling them to travel and trade freely, with all of the societal benefits this brings.

A cost benefit analysis is planned for the final phase of the project, which finishes in June 2020, and will compare this new technology to traditional bridge construction in Nepal. This will be carried out when both trial bridges are complete and traffic has started to ply. The bridges will be assessed for the benefits provided to local communities in terms of a reliable, all-season river crossing, but the focus will be on the economic benefits of construction costs, quality of construction, speed of construction and reductions in the maintenance burden.

The local roads authority embraced the project, as can be seen by this quote from Mr. Mahesh Chandra Neupane of DoLI, who is the project coordinator for ReCAP: “…the decisions and the steps taken to arrive up to here really gave me some insights of the complexity of the construction of such type of bridge. It has highly inspired us (DoLI).”

Looking Forwards

Once the benefits of this technology have been proven, the next step will be for Nepal to embrace the technology and start to construct modular bridges on a regular basis. Modular bridges should be included in a long-term policy for access provision in Nepal, so that the local roads authority has the mandate to let tenders for this specific technology.

The trials provide proof that the technology is sound, is sustainable and is appropriate for Nepal. As the designs were largely carried out in-country, this should also give local engineers and contractors the confidence to learn about the technology and implement it. A modular bridge design manual is in the process of being developed, which is aimed at supporting local engineers through the design process.

Training will also be provided in-country for local bridge engineers to demonstrate to them the principles of the design and how it should be applied. The training will also be extended to road engineers, contractors, technicians and entrepreneurs to raise awareness and understanding of the technology. The final stakeholder workshop for high level participants from relevant Government Ministries and senior roads authority staff will take place in May 2020, and is aimed at convincing decision makers to embrace the technology and to facilitate it to become mainstream in Nepal. Modular bridge construction has the potential to greatly increase the rate at which Nepal can reduce its backlog of required river crossings, in a cost effective and sustainable way.

References:

- Dhungel, D.N. and Pun, S.B. (2009), The Nepal–India Water Relationship: Challenges, Springer, Dordrecht, Netherlands ISBN 978-1-4020-8402-7.

- DoLI, (2019): Details of Bridges under construction on the LRN, Department of Local Infrastructure, Kathmandu, Nepal.

- IPTM Nepal, (2015), Approach paper on Adaptation of pre-stressed, pre-cast modular bridge construction technology in local roads network bridges, Kathmandu, Nepal.

- Kamal Pande, (2014), National Program for Motorable Bridges on Local Roads: Concept Note, Department of Local Infrastructure and Agricultural Roads, Kathmandu, Nepal.

- Quancai, X., Gaohu, L., Hao, C., Chong, X. and Biao, F. (2017), Seismic damage to road networks subjected to earthquakes in Nepal, 2015, Earthquake Engineering and Engineering Vibration, Vol. 16, No. 3. 16: pp. 649-670.